Pressure vessels

Pressure equipment with maximum allowable operating pressures above 0.5 bar pressure has been subject to the EU directive 97/23/EC since 2002 and to the successor directive 2014/68/EU, the so-called Pressure Equipment Directive (PED), since 2016.

Pressure vessels, but also pipelines, steam boilers and pressure-retaining equipment (valves, filters) are referred to as pressure equipment and must be divided into categories according to their hazard potential. The manufacturer may choose from various verification procedures such as type examination, quality assurance system or individual testing in order to meet the requirements of the Pressure Equipment Directive.

BENEFIT FROM OUR EXPERIENCE.

WE LOOK FORWARD TO HEARING FROM YOU.

We offer support in:

AD2000 – ASME – EN 13445

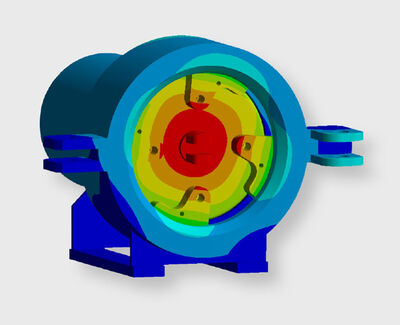

Static strength verifications and fatigue tests. Design and optimization with documentation in verifiable form.

We analyze complete systems and components such as autoclaves, reactors, agitators, heat exchangers, expansion joints, pipelines and tank systems for all load effects, such as static and time-varying pressure and temperature loads, dynamic loads, accelerations, earthquakes or explosion pressure waves.

Design review by TÜV SÜD Industrie Service GmbH. In collaboration with the experts at TÜV SÜD Industrie Service GmbH, we offer a design review of your system or plant in accordance with the regulations of your choice [AD 2000, ASME-Code, EN 13445, EN 13480, EN 14359, EN 12952/12953, CODAP 2015, PD 5500, Australian Standard AS 1210, Bolt verification VDI 2230].

Damage or problems with existing systems: We analyze possible causes and propose constructive solutions.